|

Aluminum Flood Barriers - Application Tips

Flood Barrier Considerations

The best way to

prepare for flood mitigation is with an effective plan.

Mistakes and oversights can be very costly in terms of physical

damage and dollars. Flood barriers are specifically designed and

engineered to fit an individual opening. With flood barriers,

there is no such ting as a standard issue as everything is a

retrofit! Flood gates and barriers have to take into consideration

anticipated flood heights, flow rates, impact from submerged

objects as well as application issues relating to what type of

construction we must attach to.

What to Consider

-

Must read :

FEMA

Technical Bulletin 3-93 (it is on this website)

-

Establish a Deployment Plan acceptable

to your insurance company and FEMA

-

Add Sump Pumps at

strategic locations.

-

Evaluate and use

our Flood Resistant Glazing System.

-

Verify precise

Flood Plain Elevation to avoid misunderstandings.

-

Understand that

flood protection extends 12 inches above the BFE.

-

Consider

accumulative effects of water cascading down the building.

-

Heavy rainfalls

may add to water levels inside the Flood Panel line.

-

When using the

Flood Resistant Glazing System, Consult Savannah for

precise application info, mullion spacing’s, flood water

protection

THEREFORE

A PLAN - A

STRATEGY - AN ARRANGEMENT - A TACTIC - A SCHEME - AN APPROACH - A

LINE OF ATTACK - A PREPARATION - A PLOT - A MAP - A PLAN

| Number

1 - |

Establish

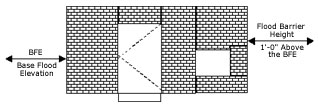

how high the barriers need to be. If legislated by the NFIP and

FEMA, it must be One Foot above the established Base Flood

Elevation for the given site. If this is not within an

established flood plane or is a Private Residence which

falls outside the NFIP/FEMA requirements, then you decide

how high the barrier is to be. |

|

|

| Number

2 - |

Evaluate

what the flood barriers are attaching to. Keep in mind that Flood barriers are

rigid rectangular panels that need a flush and even surface

on a minimum of three surfaces to attach to. (It may not

necessarily required at the top or head of the barrier as in

many cases the required height of the barrier often falls

below the actual height of the window and door opening)

Flood panels cannot walk stairs or attach to uneven

gradients or substrates. |

| Number

3 - |

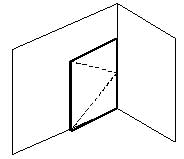

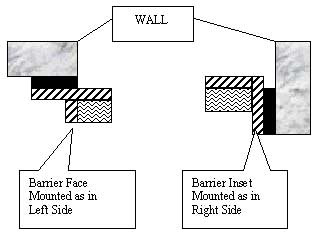

Decide on

which application best applies for each of your openings. There are two options for attaching our barrier

to a structure. Our frame, a compression type set, will

either be mounted on the face of a wall plane (face mount)

or inside a window or door cavity (inset mount).

Combinations can also be used for any given barrier as well.

For example, if a door jamb is right up against an

intersecting wall say on the right side of the door, it is

possible to have a face mounted installation on the left

side with an inset mount on the right side with the sill

also being either a standard sill or face mount in the case

of an impeding stoop or concrete step. |

|

EXAMPLE:

Elevation View

|

|

Plan View

|

| Number

4 - |

Provide

detailed information for each opening along with accurate

field measurements for pricing and engineering. Include any plans, specifications,

photos (digital ones accepted too) and allow us the courtesy

of some time to define and price your project. Once we've

performed our analysis, we shall provide you with a

qualified bid notating specific quantities sizes along with

any other pertinent information. If all is acceptable and

you give us notice to proceed we will then begin engineering

the job and provide for structural engineering calculations

and shop drawings. When completed, a submittal set shall be

forwarded to you for final approval. |

| Number

5 - |

Prepare

perimeter of window and door openings to receive flood

barriers.

Although we integrate a compression seal with a dense closed

cell neoprene, all mortar joints between brick and block as

well as tile joints need to be flushed up. This too would

apply to stucco finishes as well. Important to note too, is

that all sills need to be concrete. Asphalt and surface

toppings such as cool deck, chattahoochee and pavers are not

acceptable as a surface base. Plans for concrete or cement

should be made in advance. |

| Number

6 - |

Follow our

plans for installation. Once you've completed your final review and

acceptance of the shop drawings with any corrections or

other edits noted, we will begin to fabricate your order. At

this juncture, nothing should change to significantly alter

the intended openings that the barriers are being fabricated

for. Thus, the shop drawings become your final assembly

detail or map. By adhering to these simple rules, you can

avoid certain pitfalls and provide for a smooth process.

From the information and back up we supply, your architect

or engineer will have enough to endorse a "Floodproofing

Certificate" from our involvement. Regular rules of

course apply to the Floodproofing of Non-Residential

Structures as referenced in FEMA 102/ May 1986. |

Phone (561) 656-2556

Fax (561) 656-2599

Toll-Free (888) 640-0850

E-Mail:

Click Here

|